Unit Load Devices are perhaps one of the most important but least-known parts of the air freight industry.

It’s thanks to them that carriers can onboard cargo so quickly between flights, that goods arrive undamaged and that air freight stays a financially viable solution for importers and exporters.

In this article, we lift the lid on the containers and pallets that form Unit Load Devices, explain why they’re so important and run through the most common types of devices that will transport your cargo.

What is a Unit Load Device?

A Unit Load Device (ULD for short) is a device that restrains cargo, mail, perishable goods and baggage during air transportation. This is either the solid metal containers you’ve probably seen at an airport or a pallet with mesh netting that holds the contents in place.

ULDs have been common in the aviation industry since the 1950s. There were a range of different shapes and sizes at first, but standardisation has been commonplace since the IATA formalised the use of ULDs in 2013.

There are several different types of ULDs designed to fit into the holds of pretty much every common aircraft. Like with shipping containers, you can also get specialised ULDs, such as reefers that control the temperature.

What Are the Benefits of ULDs?

The creation and proliferation of Unit Load Devices has made things a lot easier for airlines transporting additional cargo. First and foremost, it removes the need to manually load an aircraft prior to take off. Being able to insert pre-loaded units into an aircraft saves a tremendous amount of time and helps to streamline the entire supply chain. Units can be loaded well in advance and positioned to await aircraft at gates.

ULDs also make it easy to transfer cargo between one aircraft and another. Assuming the cargo is packed into a ULD that fits both planes, it’s a relatively simple operation to move goods quickly between aircraft when additional flights are required.

The protection that ULDs — especially containers — offer cargo is second to none. When packed appropriately, the sturdy and durable nature of ULDs means goods can’t move around and get damaged during flight. In addition, this ensures cargo is kept in the correct position for weight and balance purposes.

There is even an environmental benefit to using ULDs. Their space-saving nature means cargo space can be optimised to the point where fuel consumption is reduced.

What are the Different Types of ULD?

There are two types of ULDs: containers and pallets. Which type and shape of ULD carriers will use depends on the aircraft and the shape and weight of the cargo.

Pallets are large, flat metal plates. Cargo is placed on top of the pallets and held in place using nets or mesh. Pallets offer a flexible solution since the way goods are stored can be adapted to fit the contour of the plane.

Containers are the air freight equivalent of shipping containers, but they come in a much greater variety of shapes and sizes. That’s because they need to fit the specific measurements of the different aircraft used. In other words, a container that fits in a Boeing 767 won’t fit into an Airbus A380.

Here is a rundown of the most common pallets and containers:

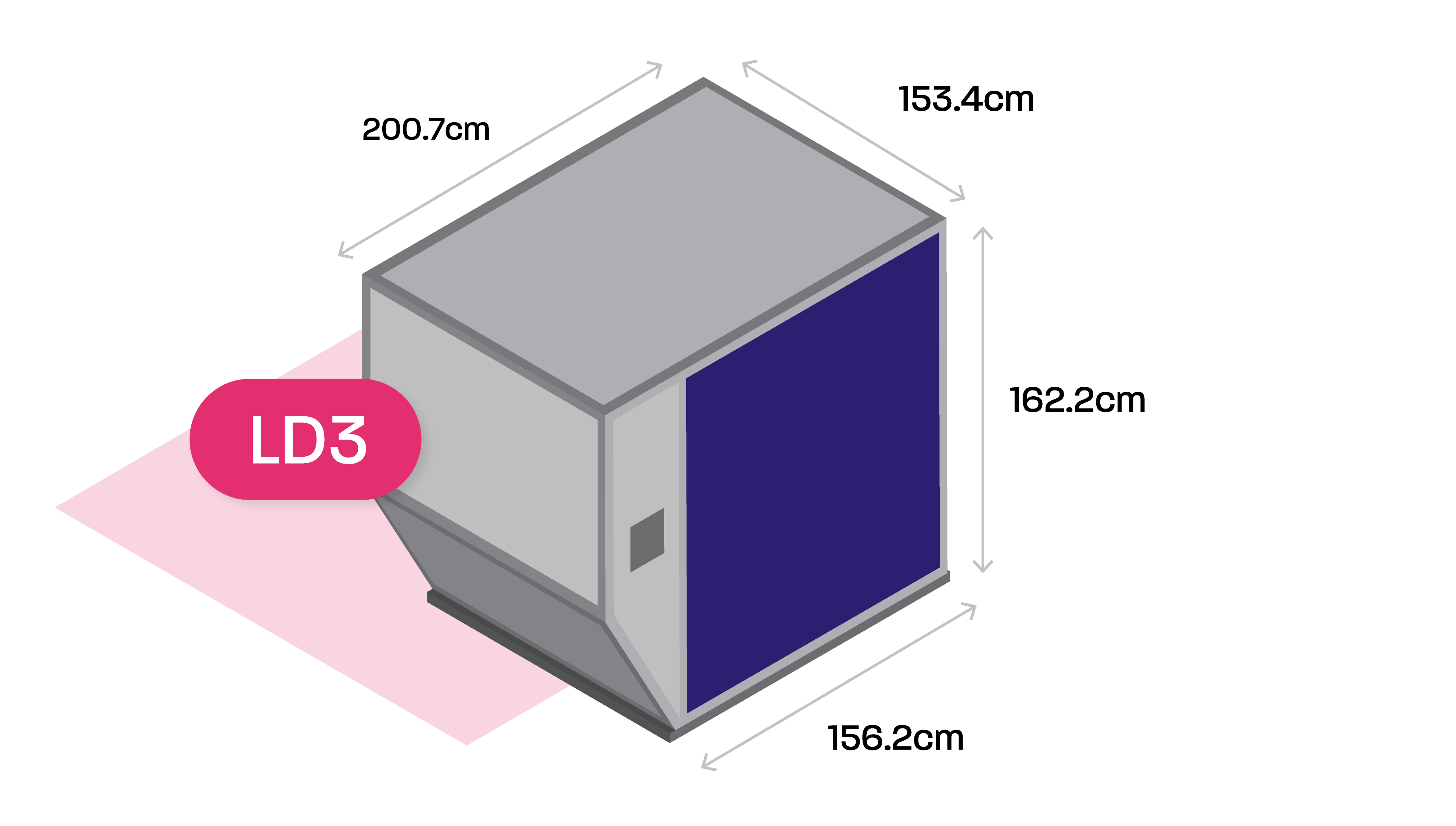

The LD3

The LD3 is the most common ULD container. It can be used on most widebody Airbus and Boeing aircraft, as well as smaller aircraft from a range of different manufacturers.

| IATA ULD Code | AKE, DKE, MKE, QKE, RKE |

| Aircraft Suitability | A300, A310, A330, A340, A380, B747, B767, B777, B787, DC-10 and others |

| Maximum Gross Weight | 1,588 kg |

| Volume | 4.3 m3 |

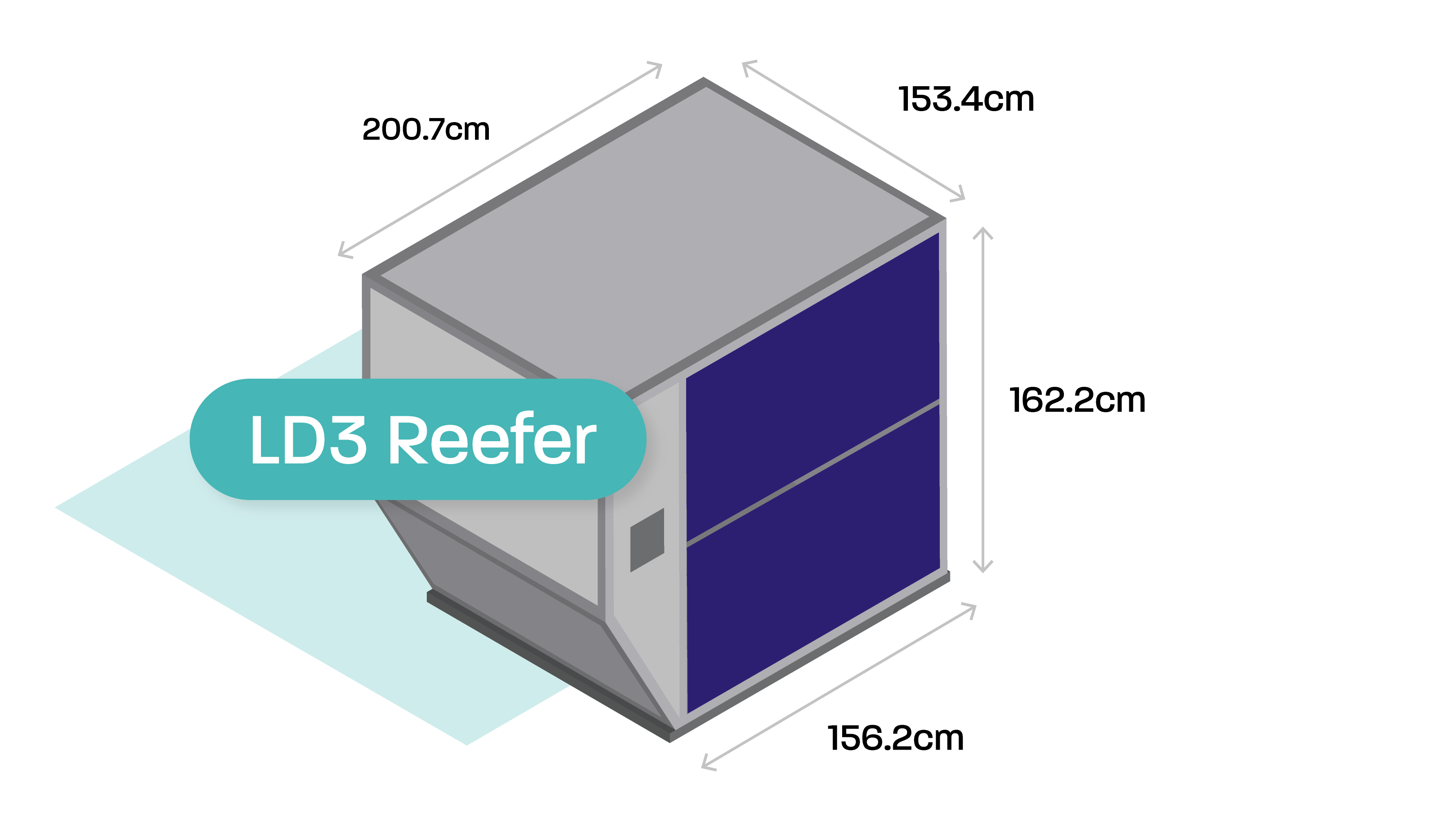

The LD3 Reefer

The LD3 Reefer is a temperature controlled version of the LD3 container. The Reefer boasts a 70-hour battery life that can keep the temperature anywhere between -30°C to +50°C.

| IATA ULD Code | RKN |

| Aircraft Suitability | B747, B767, B777, DC10, M11 lower hold |

| Maximum Gross Weight | 1,588 kg |

| Volume | 4.5 m3 |

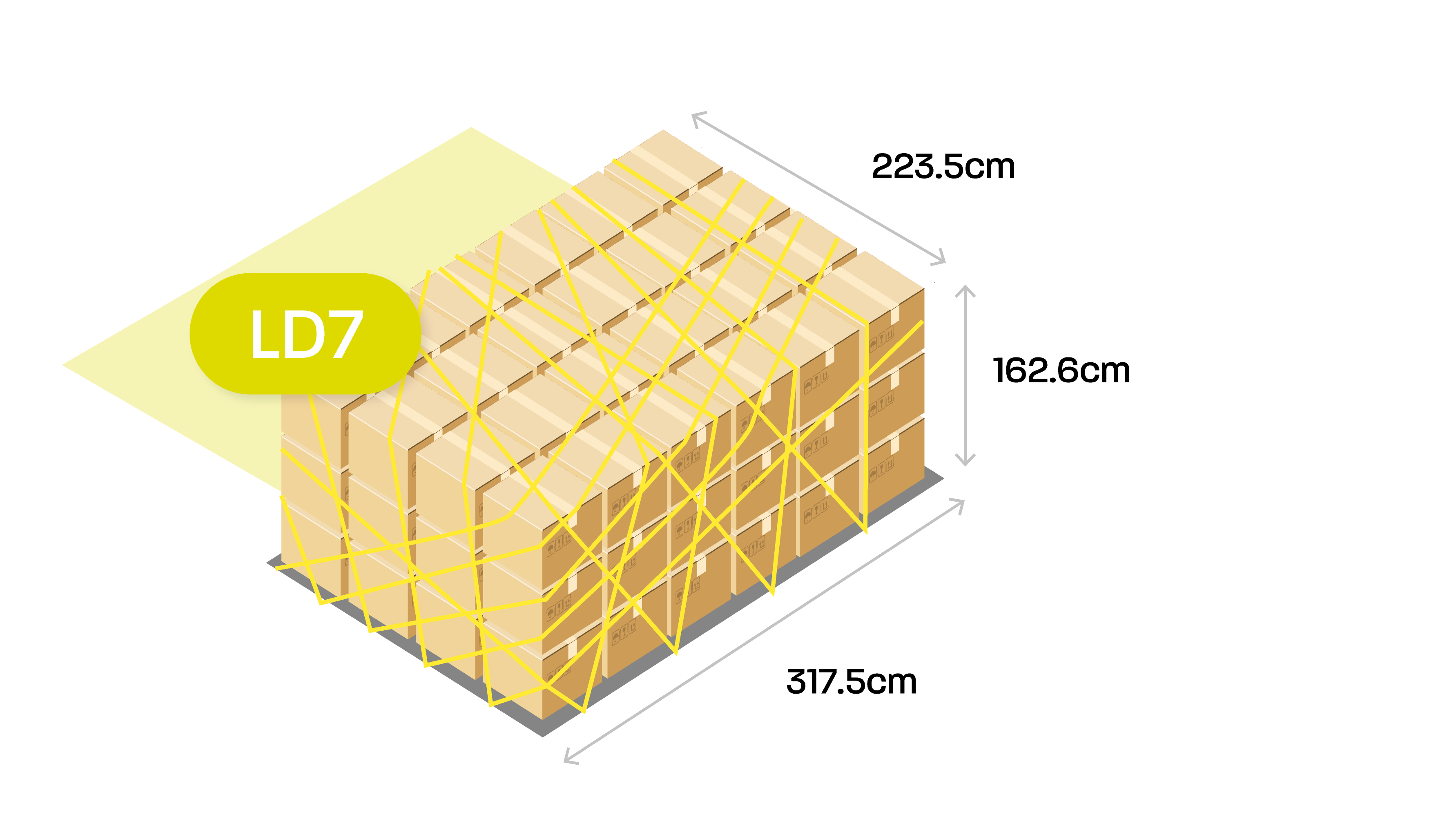

The LD7

The LD7 is a double-width flat pallet and net. It can come with or without angled wings to suit a variety of aircraft.

| IATA ULD Code | P1P pallet |

| Aircraft Suitability | 747, 777, 787, DC-10, MD-11 lower holds |

| Maximum Gross Weight | 5,000 kg |

| Volume | 14.0 m3 |

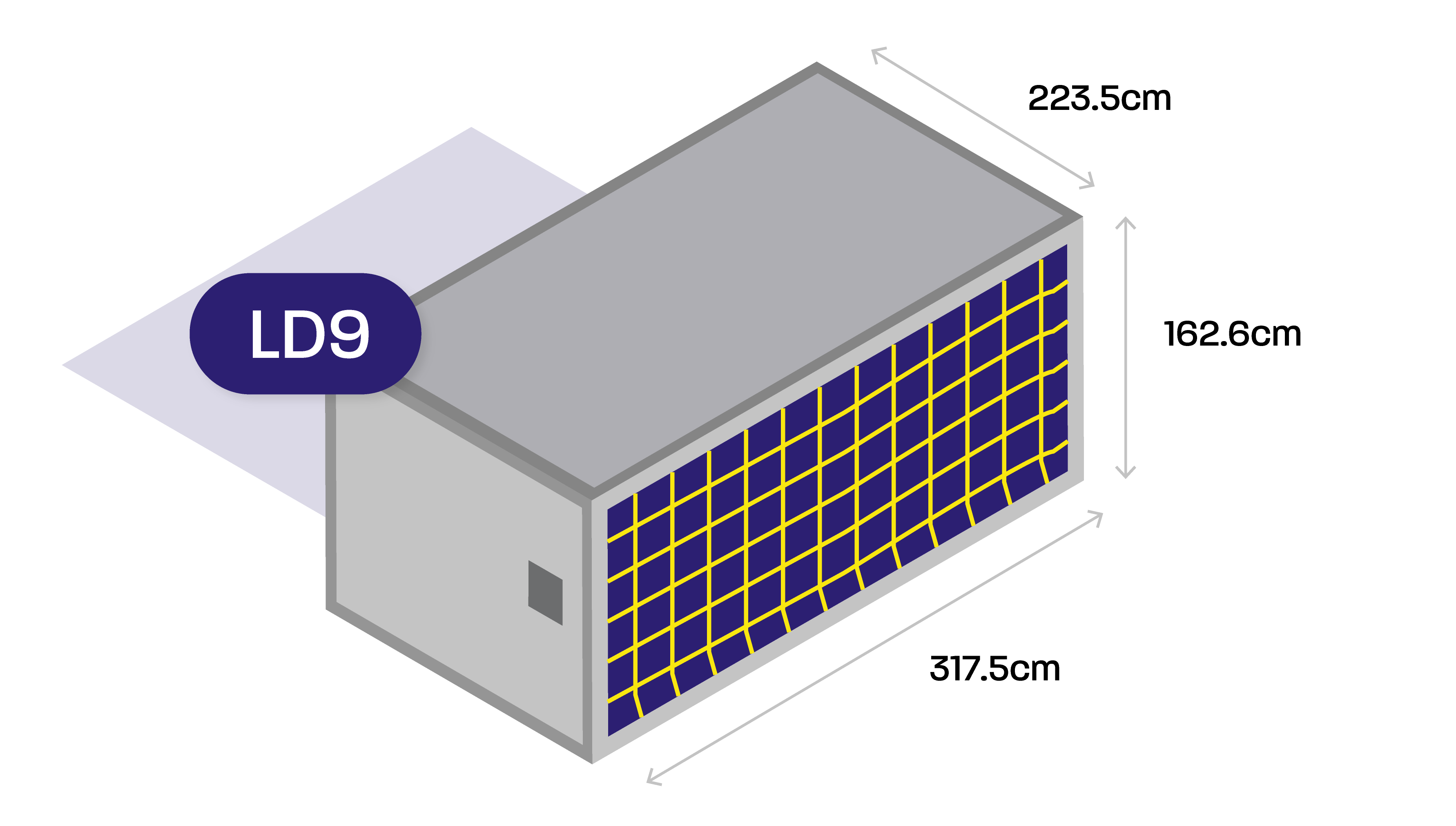

LD9

The LD9 is a rectangular multi-purpose container that can come completely enclosed or with a mesh netting front.

| IATA ULD Code | AAZ, AAP, RAZ, RAP |

| Aircraft Suitability | A300, A310, A340, B747, B767, B777, B787, DC-10, MD-11 |

| Maximum Gross Weight | 6,000 kg |

| Volume | 9.8 m3 |

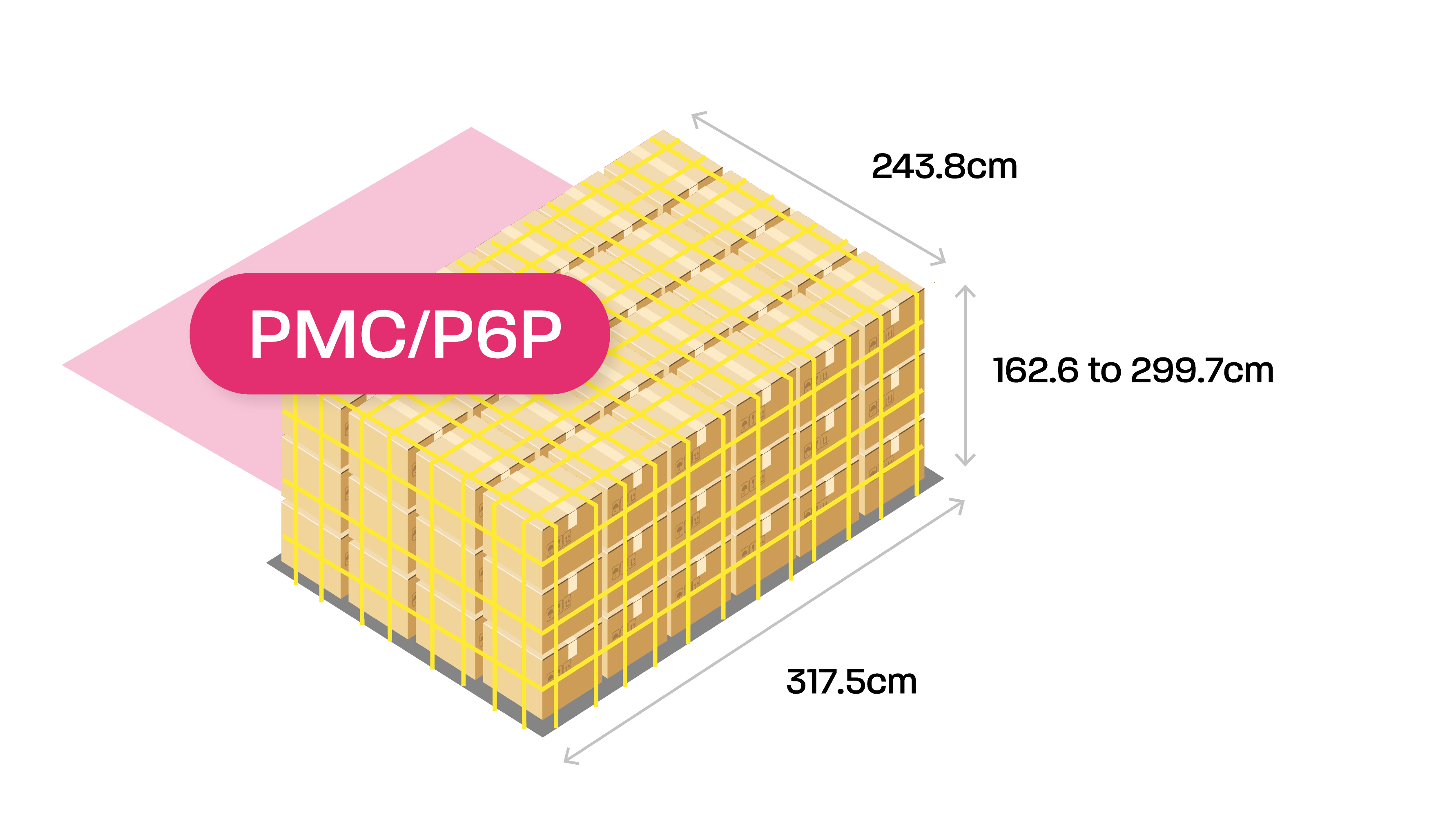

PMC/P6P

The PMC/P6P is a universal general purpose flat pallet that can be stored on lower hold and main decks in a variety of Boeing and Airbus aircraft.

| IATA ULD Code | P6C, P6P, PQP, PMC, PMP |

| Aircraft Suitability | A300, A310, A340, B747, B767, B777, B787, DC-10, MD-11 |

| Maximum Gross Weight | 6,800 kg |

| Volume | 11.5 m3 - 21.2 m3 |

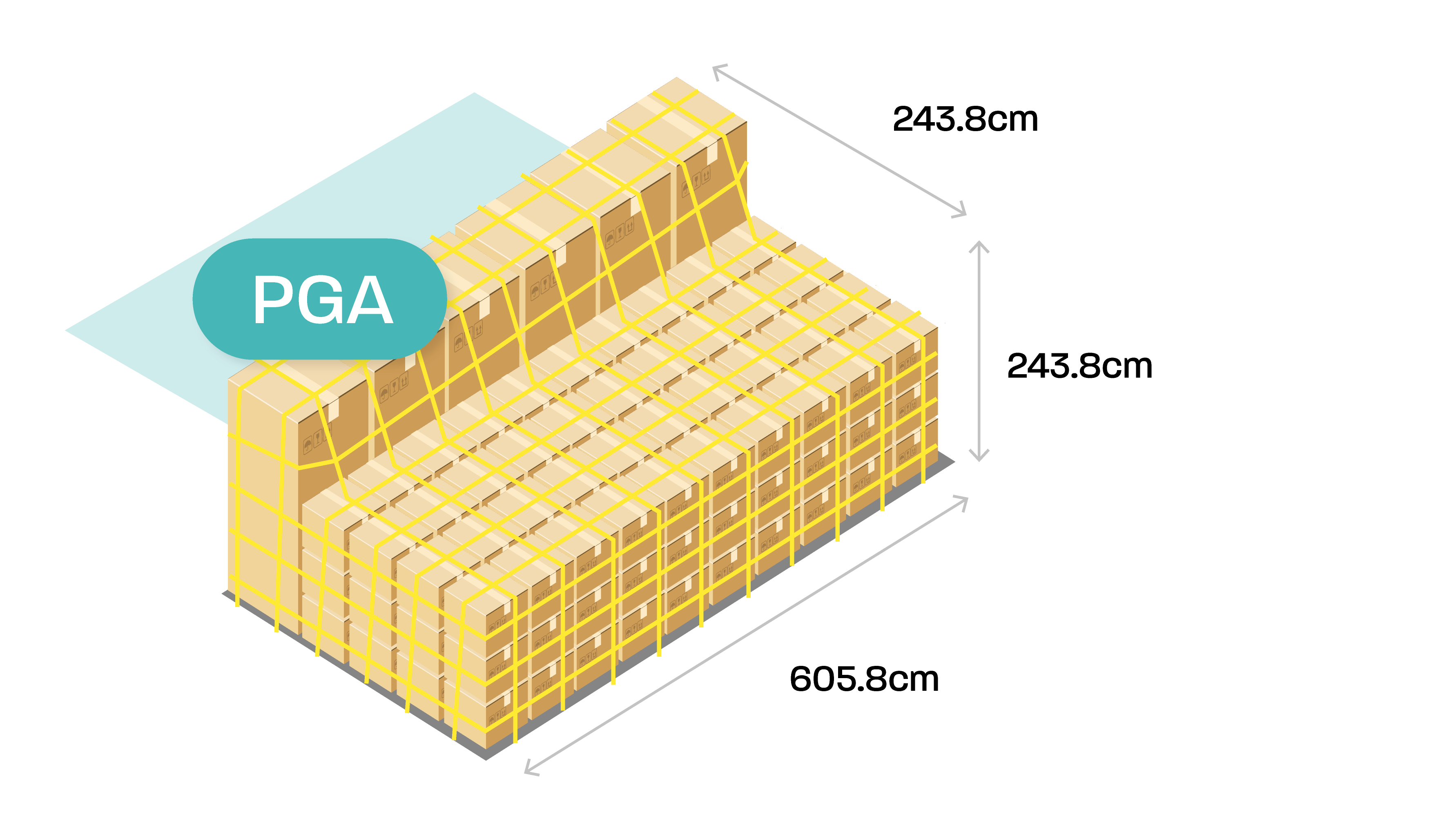

PGA

The PGA pallet is a heavy-duty flat pallet with a mesh netting that can withstand oversized cargo due to its increased strength and durability.

| IATA ULD Code | P7A, P7E, P7F, PSG, PGE, PGA |

| Aircraft Suitability | B747-MD |

| Maximum Gross Weight | 11,340 kg |

| Volume | 21.2 m3 |

Finding the Best ULD For Your Cargo

Hopefully, you’re now a lot clearer on the different types of Unit Load Devices that ship your cargo by air. The good news is that even if you aren’t Pro Carrier are here to help! The benefit of working with an expert freight forwarding company like Pro Carrier is that we’ll ensure your goods are shipped by an air freight route that meets your needs — whether that’s speed, cost or something else -— and your cargo will always be placed in the right ULD.

It’s our goal at Pro Carrier to ensure you have the most seamless and stress-free experience possible. That’s why you don’t just get our expert advice or competitive rates, you also get industry-leading customer service and access to Horizon, our free digital supply chain solution.

If you’re looking for a long-term air freight partner who knows how to put your needs first, then speak to a member of our team today.